From Pixels to Shape: The GreenDot Engine Story

Many photo-to-3D tools aim first to look convincing. GreenDot starts with the opposite priority: preserve the geometry. Edges should remain edges. Cylinders should stay cylindrical. Symmetry should not drift. When an engineer measures the flange in AR, or when a curator inspects a carved motif in VR, the model has to behave as the real object would.

On a workbench sits a small industrial valve. The marketing team needs a 3D model for the website. The design group wants to check clearances in VR. The training team plans a short safety module for new hires. There is no studio booking, no turntable, no LiDAR. There is only a phone, ten minutes of time, and the hope that a few photos will be enough.

This is the moment GreenDot Engine was built for. Not the perfect capture with dozens of images, but the ordinary one: a handful of angles, mixed lighting, a background that’s not entirely cooperative. The question is simple and scientific at the same time: from limited measurements on a surface—pixels with perspective—can we recover the object’s true shape?

The geometry-first idea

Many photo-to-3D tools aim first to look convincing. GreenDot starts with the opposite priority: preserve the geometry. Edges should remain edges. Cylinders should stay cylindrical. Symmetry should not drift. When an engineer measures the flange in AR, or when a curator inspects a carved motif in VR, the model has to behave as the real object would.

To achieve that, the engine treats every input photo as evidence in a geometric experiment. If two photographs disagree about a surface, the decision favors the configuration that keeps the mesh manifold, the normals coherent, and the curvature stable. Texture is added later; the shape comes first.

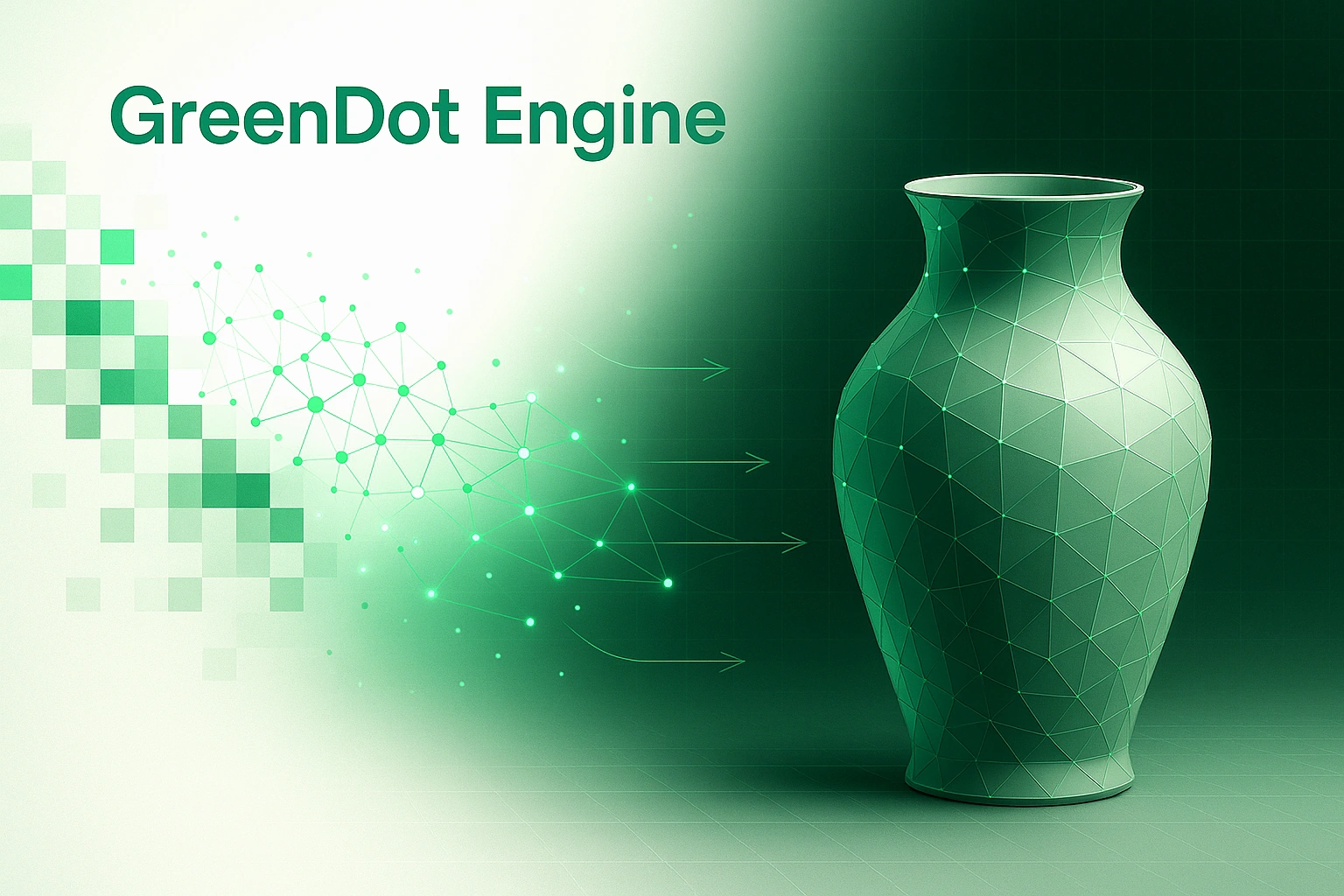

Pixels → dots → mesh

A short version of the pipeline, without heavy math:

-

Pixels become features. We extract contours, corners, and shading cues that survive viewpoint changes.

-

Features become structure. Multi-view consistency links those cues across images, forming a scaffold.

-

Structure becomes an implicit shape. A learned field fills in what the cameras did not see, guided by priors about real objects.

-

The implicit shape becomes a mesh. We extract a surface, remove self-intersections, and remesh with attention to curvature.

-

The mesh becomes an asset. UVs are unwrapped, textures are baked, and levels of detail are generated for the web or XR.

At each step the objective is geometric fidelity. The engine tries to minimize distance between the recovered surface and the one implied by the photos, while keeping normals, edges, and symmetry consistent. In practice this means thin parts do not melt, fillets stay smooth, and flat panels do not ripple.

Field notes from four very different days

Day one is e-commerce. A furniture brand needs a dining chair online in 3D by tomorrow. Twelve photos around the piece, a few higher and lower, soft window light. The engine flags a weak region under the seat and recommends two extra angles. The final model loads in a web viewer at under two megabytes; the legs remain straight, the seat retains its subtle saddle curve, and the joinery edges read cleanly even at close zoom. Customers can rotate, try AR, and the marketing team never opens a modeling tool.

Day two is training. A technician will learn how to orient a heavy drill safely. Geometry matters here because the drill must block light correctly in the VR scene and collide with virtual fixtures as expected. The capture has glossy highlights and a dark handle. The engine’s masking and normal-consistency checks stabilize those regions; the resulting mesh keeps the handle round and the chuck threads recognizably helical. The scene’s lighting behaves, and the training designer spends time on pedagogy instead of cleanup.

Day three is a design review. A supplier sends nine photos of an HVAC damper, taken on the factory floor. There are vents, louvers, and a narrow axle. Thin parts often fail in casual reconstructions; here, extra views are requested for the axle and the louver edges. The geometry-first remesher preserves those edges, and the optional watertight setting ensures the part can be inspected in section view without artifacts. The team finds an interference early, saving a week.

Day four is cultural heritage. A small clay figurine must be archived quickly during a field visit. The background is improvised; light is uneven. The engine’s symmetry hints stabilize the torso, while curvature-aware refinements retain the shallow relief on the chest. Texture helps the story later, but the value lies in the shape: a faithful silhouette, correct volumes, and smooth transitions that survive re-lighting in the museum’s web app.

Measuring what matters

To keep promises about geometry, we monitor a few simple indicators on sample sets:

-

Chamfer distance to gauge average surface error.

-

F-score at a small threshold to balance precision and completeness.

-

Normal consistency so flat walls remain flat and curved rims stay smooth.

-

Basic mesh health: watertightness and absence of self-intersections.

These numbers do not guarantee perfection, but they keep the engine honest about shape, not just appearance.

How to take photos when geometry is the goal

Parallax beats zoom. Walk around the object and keep it large in frame. Choose eight to twelve angles that cover front, back, sides, and a couple high and low viewpoints. A matte background and even light reduce specular confusion. Spend a little extra time on thin parts and openings. If physical proportions matter, include a small scale tag in one frame.

The web app will nudge you if coverage looks weak; it is easier to add two extra photos than to repair a missing edge.

What you receive

Outputs are simple: a clean triangular mesh in GLB/GLTF for web and AR, with optional OBJ/FBX for DCC tools. Textures follow common PBR channels for realism. Levels of detail are included so a model can load quickly on mobile and refine when needed. A short report highlights coverage and basic geometry health, useful for audit trails or design discussions.

Where this fits in a team

GreenDot does not replace high-end scanning when microns matter, and it will not turn four snapshots into a CAD drawing. It fits the common case where a believable and geometrically sound mesh unlocks progress: a product page that ships today, a training module that communicates clearly, a review where stakeholders see the true form and agree on a decision.

Availability

Private Preview is open now for a limited number of partners under NDA. Public Alpha begins January 2026, followed by a closed beta in April and general availability in early summer.

If your bottleneck is not the texture but the shape, we would like to hear about your use case.

Apply at /greendot#apply or email [email protected] with the subject “GreenDot Preview”.